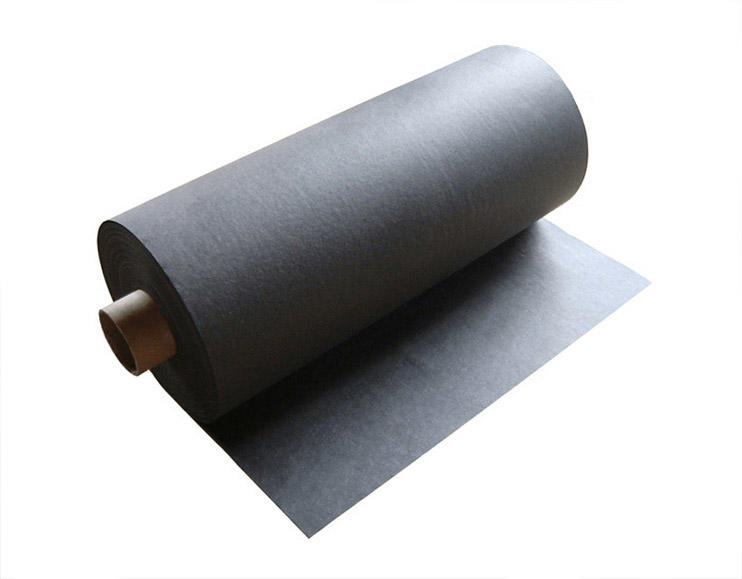

The main materials of

spunbond non-woven fabrics are polyester and polypropylene. The world's spunbond non-woven technologies mainly include Lacoffel technology from Reifen, Germany, STP technology from Italy, and Kobe Steel technology from Japan. The current situation, especially with Reffin technology becoming the mainstream technology in the world. It has now developed to the fourth generation of technology. It is characterized by the use of negative pressure ultra-high-speed air drafting, and the fiber can be stretched to about 1 denier.

.jpg)

What is the process flow of spunbond non-woven fabrics? The process flow of spunbond non-woven fabric is as follows:

Polypropylene: polymer (polypropylene + return material) - large screw high temperature melt extrusion - filter - metering pump (quantitative conveying) - spinning (spinning inlet and outlet stretching and suction) - cooling - Air Traction - Net curtain forming - Upper and lower pressing rollers (pre-reinforcement) - Mill hot rolling (reinforcement) - Winding - Reverse distribution and slitting - Weighing and packaging - Finished product storage

Polyester: processed polyester chips - large screw high temperature melt extrusion - filter - metering pump (quantitative conveying) - spinning (spinning inlet up and down stretching and suction) - cooling - air traction —— Net curtain forming —— Upper and lower pressing rollers (pre-reinforcement) —— Hot rolling of rolling mills (reinforcement) —— Winding —— Reverse distribution and slitting —— Weighing and packaging —— Finished product storage.

.jpg)