Sterile barrier properties are lost after use

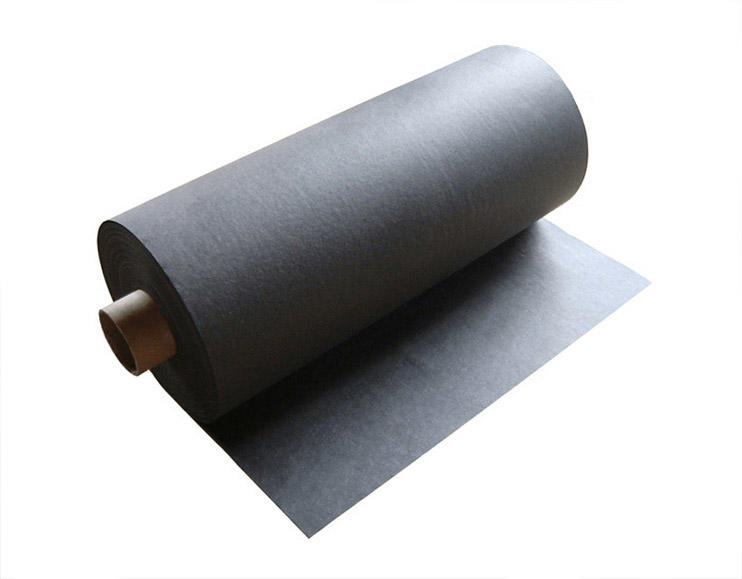

According to research, the shelf life of sterile items is closely related to the thickness of the

non-woven fabric and the number of layers of the wrapping. Disposable non-woven packaging materials, after a series of high temperature steam sterilization and chemical washing, the fiber structure is deformed, the cloth holes are sparse, the thickness decreases, and even small holes that are not easily detectable by the naked eye appear, the antibacterial rate will suddenly drop or Loss of antibacterial performance.

The internal microscopic properties change after sterilization

Non-woven fabric packaging materials are generally SMS composite non-woven fabrics. The main material of this type of non-woven fabric is polypropylene, which is processed through multiple processes through meltblown and spunbond processes, and the microstructure is fine plastic fibers. Shrinkage after encountering high temperature is a characteristic of plastic articles. There is no real high-temperature-resistant plastic, and high-temperature resistance is also a relative concept, so non-woven fabrics will also have a corresponding shrinkage reaction in the microscopic view.

After high temperature sterilization, the fine plastic fibers of the non-woven fabric will shrink to a certain extent. In use, the non-woven fabric after sterilization is more brittle than the one before sterilization, and the flexibility is reduced. The change of non-woven fabric packaging materials is one of the reasons why non-woven fabrics can only be used once.