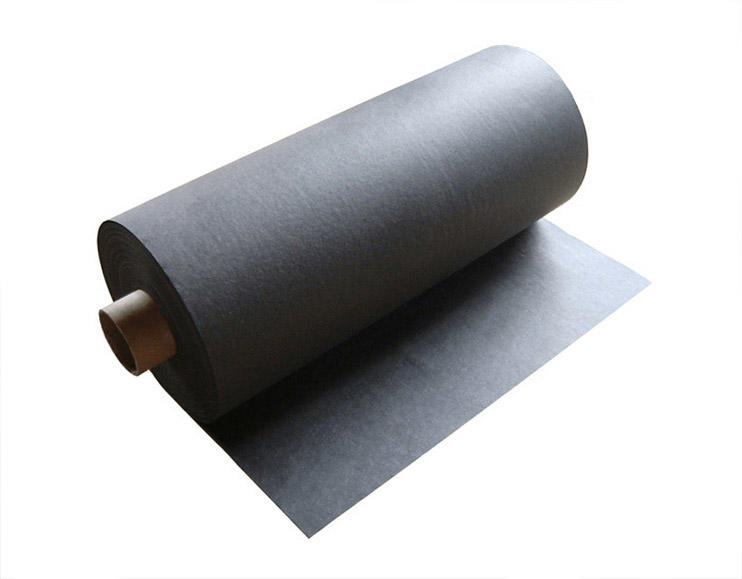

Polyester is the main component of needle-punched

non-woven fabrics. Polyester fibers are chemical fibers, which are the polymerization products of phthalic acid or diethyl terephthalate and ethylene glycol. They have high strength, good elasticity, good heat resistance and surface It has the characteristics of smoothness, good wear resistance, corrosion resistance and poor dyeability. Mainly, flame retardants are added to materials, and flame retardants are additives for materials. It is generally used in polyester plastics, textiles, etc. It is added to polyester to increase the ignition point of the material and hinder the combustion of the material to achieve the effect of flame retardant, thereby improving the fire safety of the material. There are many types of flame retardants, such as halogen-based flame retardants, organophosphorus and phosphorus-halogen flame retardants, intumescent flame retardants, inorganic flame retardants, and brominated flame retardants in halogen-based flame retardants. most used.

.jpg)

Needle-punched non-woven fabrics can be divided into flame-retardant needled cotton and flame-retardant hot-air cotton according to the process. Needle-punched non-woven fabrics are made of entangled fibers after being punctured by acupuncture machine; Furnace made. Both products have their own advantages, the common features are flame retardant, light, warm, durable and environmentally friendly.

.jpg)