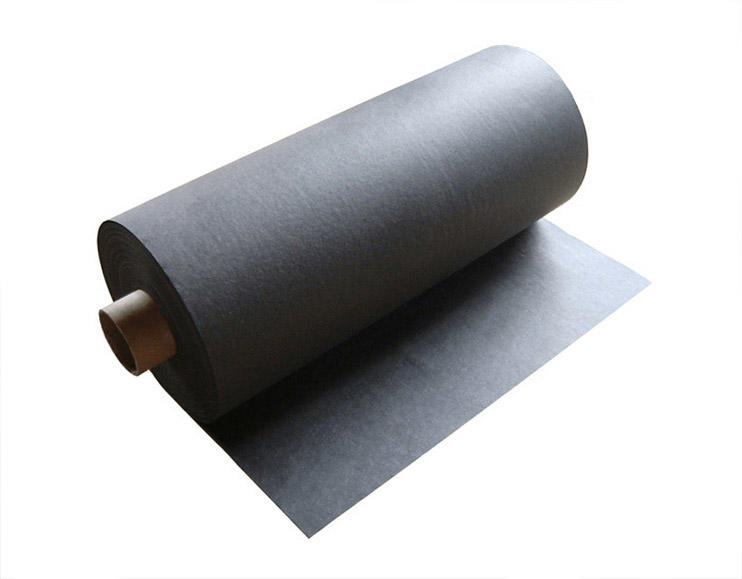

Geotextile, also known as geotextile or non-woven fabric, is a water-permeable geosynthetic material made of synthetic fibers through needle piercing or weaving. Geotextile is one of the new materials and geosynthetics. The finished product is cloth-like, with a width of 4-6 meters and a length of 50-100 meters. Geotextiles are divided into woven geotextiles and non-woven short filament filament geotextiles.

1. High strength, due to the use of plastic fibers, it can maintain sufficient strength and elongation in dry and wet conditions.

2. Corrosion resistance, long time corrosion resistance in soil and water with different pH.

3. Good water permeability. There are voids between the fibers, so it has good water permeability.

4. Good anti-microbial properties. No damage to microorganisms and insects.

5. Convenient construction. Because the material is light and soft, it is convenient to transport, lay and construct.

6. Full specifications: width can be customized, mass per unit area: 100-1000g/m2

The non-woven fabric has no warp and weft threads, and it is convenient for cutting and sewing, and it is light and easy to shape, which is very popular among craft lovers.

Because it is a kind of fabric that does not need to be spun and weaves, it just oriented or randomly arrange the textile short fibers or filaments to form a web structure, which is then processed by mechanical, thermal bonding or chemical methods.

It is not interwoven and knitted together one by one yarn, but the fibers are directly bonded together by physical methods, so when you get the sticky scale in your clothes, you will find that, It is impossible to draw a single thread. Compared with the traditional textile principle, non-woven fabrics have the characteristics of short process flow, fast production rate, high output, low cost, wide use, and multiple sources of raw materials.